Bespoken Word: No such things as standards

Guy Kesteven talks about the problems of being the personal shopper for the Emperor’s new clothes

A couple of weeks ago I argued that things that seem freaky at first are often pointers towards significant advantages. But at what point do ‘we’ decide things have gone too far? What's the difference between a bandwagon the bike industry piles onto, and a band that nobody turns up to hear? Let’s take a trip through history to see if we can learn some lessons.

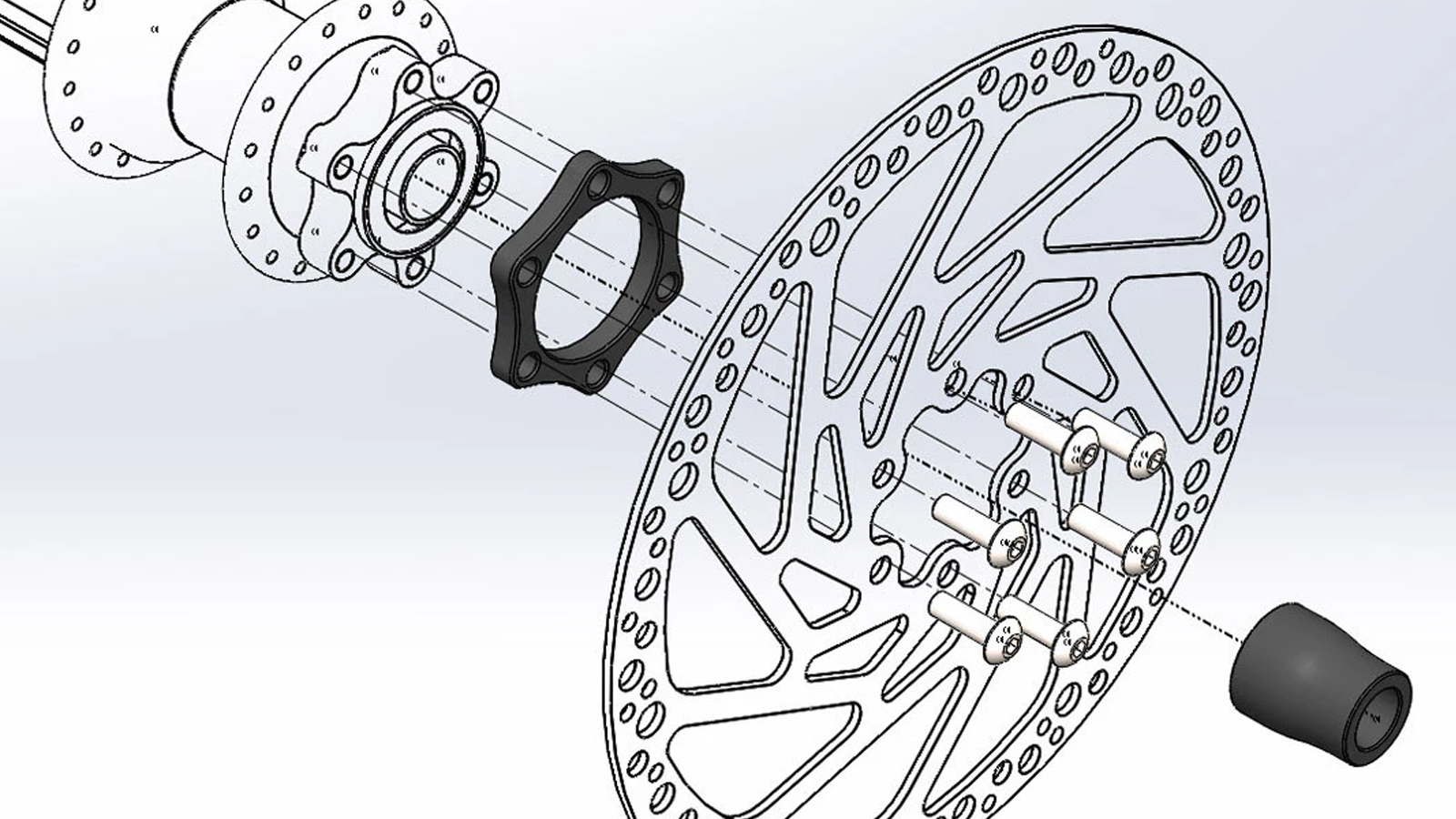

First, let’s be clear here. I have no vested interests in promoting change for change’s sake. OK, so it might give me a bit more to talk about, as I hate changing standards for a whole bunch of reasons. I’ve lost countless hours where I could have been test riding, writing or doing other enjoyable stuff, rather than realizing too late that I don’t have the freewheel, cassette or rotor type I need to work on those wheels which I’ve already swapped tires on. Or rooting frenziedly through boxes and drawers to find different end caps to get something to fit when road/cross/gravel bikes were still yo-yoing between QR, 15 and 12mm in 135 or 142mm widths. Trying to find different valve adaptors when RockShox and Marzocchi had their own different designs, or that day I realized that between Shimano, SRAM and Sachs there were currently 11 different ways I could change gear on a mountain bike. Including three different ratios of twist and completely reversed lever actions in either trigger or flappy brake lever versions. That genuinely nearly sent me over the edge and I still have a weird Pavlovian twist to shift reaction on grips with a fatter inboard section despite it being a decade since I used Gripshift.

Non-standard standards

Back then I was also a custodian of one of the most comprehensive 26in test tire libraries in the world. A collection built up over 15 years of gradual MTB tire evolution and that had become big enough to take up its own lock-up garage as well as a significant amount of my workshop. Each tire was already tested and logged in Excel sheets but was also waiting ready to refresh impressions and draw comparisons with occasional new rubber launches. And to be honest the switch to 29er wasn’t so bad. I got into it very early and it took a long time to catch on, 27.5in was a nightmare though. One minute there was that one Pacenti/Panaracer tire available in the new size and then a couple of months later I had to test 15 new tires for a group test because Eurobike was full of mid-sized wheel machines. That was comparatively easy compared to trying to test the sudden flood of new-sized wheels, especially as many manufacturers decided to change other dimensions or components too. The only good thing about that was I convinced the tax man that a custom full suspension tandem was the only way I could put month’s worth of accelerated load through test wheels in just a few weeks. And then 27.5 briefly got really wide as 2.8-3in Plus tires were the high volume vogue for a couple of years, then it shrunk a bit back to 2.6. And then 29ers launched their counter-attack with wider wheels and tires plus new 148mm Boost axle sizing.

As wheels and tires changed so did frames and forks and axle standards, all complicating and confusing the component and geometry algorithm that creates the character of a complete bike. Is the bike tracking better because of that new tire? The wider rim? The wider axle? The new frame? One of those things? Two? Three? Or all four but in what proportion? That’s a 16-step process of elimination before you even start suggesting what you could swap in to sort any issues. In other words, changing standards totally shifts the testing landscape and creates masses of work rather than just a small tweak of the existing environment. And that really sucks when you’re on word rate, not hourly.

There are other people in the industry who have it far worse than testers too. While jumping on the right bandwagon early can give a brand an edge, judging when or whether to jump is a massive gamble with production schedules and resources. Worse still it often has to be done with only prototype pieces to try before they buy thousands of units. Or when things are changing really fast, they might have to stake everything just on a promise of what a new tweak or component will do. I know for a fact one UK brand who had to hold their carefully crafted 26in range in limbo at the last minute while they bought an early 27.5 bike from a local shop so they could strip it down and frantically fast track their own experiments before completely rewriting plans they’d spent months refining. If you work in a bike shop you don’t need me to tell you that while a new ‘must have’ can help sales, it also inevitably creates a whole load of ‘must get rid of’ stock. It also complicates and multiplies spares and repairs issues and creates a lot of cheesed-off customers who’ve just invested in the previous ‘standard’.

Incremental evolution

So if changing standards creates so much work, why does it happen so often? Because I guess in short we are, as homo sapiens — especially ones with an engineering or competitive sport agenda — an evolution-addicted species. While mindfulness and contentedness are beautiful things, even the briefest glimpse at history will show a seething mass of industrial, military, scientific, sporting and social one-upmanship. And by and large that works out well for the bikes we ride. Especially if you’re patient enough to sit out the first rush to a new technology and benefit from it in a mature and well-supported format. But even those now saddled with a tiny chainring e-bike that becomes immovable when the battery dies have helped fund the development of more useable machines. In the same way that people who bought DAT machines or Picture Disc players are a key — if misdirected - step in the evolution of how we consume music.

In a lot of cases, developments of standards are sequential and understandable. The move from 130 to 135mm on early MTBs gave space for gears, then we got through axles and super-wide 150mm axles to make DH bikes stiffer. But here’s a classic case of where things got confused: rather than making the leap to the existing much-wider-and-obviously-stiffer standard, we crept to 148mm via 142, which then became a road bike standard as the drop bar crowd took disc brakes on board too.

Each step was small to not make consumers choke on a suddenly wider pedal stance or other issues, while ultimately adding layers of obsolescence. And now we’ve got SuperBoost, which is effectively just a rebranding of that old 150mm standard and as far as we can tell from the rest of the bike performance algorithm, does make things stiffer. Even after several years campaigning for acceptance from brands like Pivot and then Evil, if you list SuperBoost as a feature on a new bike — see Saracen’s Ariel launch this week for details — it’s definitely getting hate not hearts in the comments. Especially when you get seemingly futureproof combinations like SuperBoost width with extra linkages to swap to a mullet back wheel, but that wheel is going to be really awkward to find right now and that same back end uses an outdated IS disc brake mount.

And as much as the conspiracy theorists would love the idea of some industry cabal that cynically manipulates the future of bikes and keeps consumers dangling over built-in obsolescence like desperate puppets, I’ve certainly never had an invite to the cauldron party. I also get enough calls from people asking if I know what other people are up to or what move they should make next to suggest that I’m not the only one deep in the dark if it is happening.

Reinventing the wheel

It doesn’t help that some trend flows are just emotional/marketing-led rather than engineering based too. We already had a well-developed 20mm front hub and fork infrastructure, but because most of those designs were seen as DH those axles and hubs were deemed to be too fat for trail riding and its more lightweight sensibilities. That’s despite the fact that oversizing both components potentially made them stiffer and/or lighter and at the time nearly every fork had 32mm legs so using a 20mm axle made a real measurable difference on designs like the original RockShox Pike. Somehow 15mm stuck though, and now even though we’re using 38mm legged forks the massive legs are still pinned together at the bottom with axles only 3mm fatter than road bike spindles. Unless you run a DH bike, where you’ve always had the stiffer simplicity of 20mm axles.

After upsizing to 1.5in diameter straight steerers for maximum stiffness a couple of decades ago, we’ve stepped back on dimensions at the top of the fork too. I can remember lots of figures flying around at the time in terms of tapered steerers saving a lot of weight for minimal stiffness loss, but surely now with us smashing bikes into stuff harder and faster than ever it’s time to reconsider. Actually, several brands are using massive headtubes and matching forks on their e-MTB’s - as much for the looks as the engineering advantage - but nobody big has done it yet.

And that is often the driving factor behind manufacturers getting behind a new standard or not. It’s generally accepted that it was the European brands that got left behind when 29ers took off in the US and instead championed 27.5in wheels as the ideal compromise. Just so they could save face and look like they were on the nose of tech advancement rather than playing catch up. I can even remember being told by someone at SRAM that although they thought 170mm brake rotors to match 27.5in wheels and reflect a midpoint between 26 (160mm) and 29 (180mm) were a stupid idea, if a company was going to order thousands of them it was happy to make them.

On a similar note, I can remember sitting awkwardly through a Ritchey presentation based entirely around the new 31.7mm bar and stem standard until someone eventually pointed out that the new standard was 31.8mm. Did that 0.1mm matter in engineering terms? No. Were the products probably 31.8mm or near as damn it anyway? Probably. Did that mean we all quietly shuffled out of the show and tell without even bothering to take the water bottle and sock schwag? Yes. But what were all of us fickle idiots raving about, having seen it on the trail when we got in the bar that night? A prototype Maverick fork with an inverted design and a totally unique 37mm axle hub. It cost an absolute fortune, but it was the brainchild of RockShox pioneer Paul Turner, so it had to be cool. Twenty years on, Ritchey is still making very good, lightweight cockpit equipment in a range of diameters, but Maverick died in a pool of its own shock oil and service issues just a few years later.

The next new thing

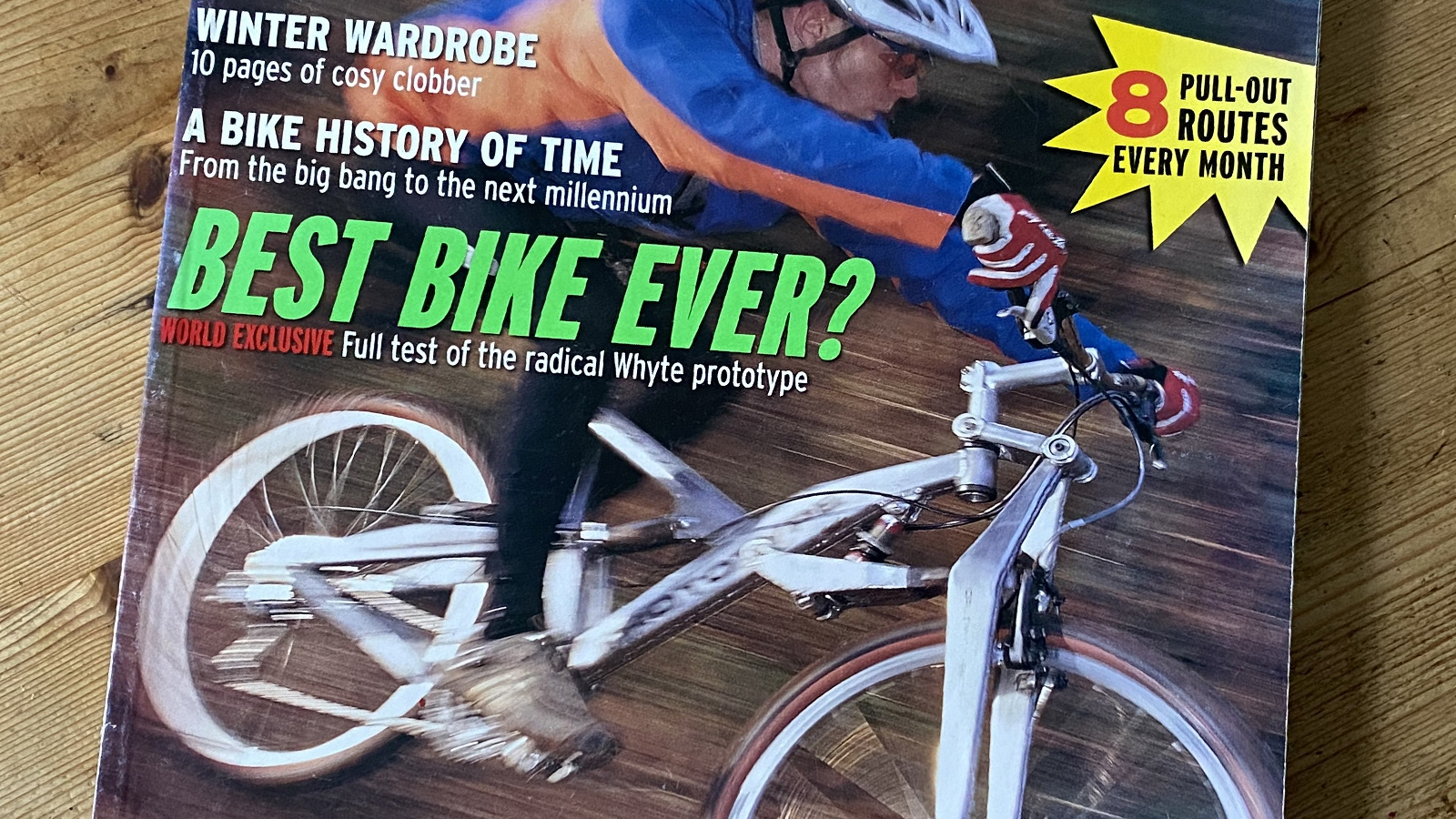

And yes that makes us jerks, but in our defense we’re being jerked around by the demands of our customers too. We wet our shorts about those crazy forks because we knew that something so radical would make people excited. Six inches of super plush travel at an XC weight made us excited and so we were desperate to try it so our readers could find out about it first and bookmark our publication with the best insight and connections. And then by the time we were having awkward conversations with Maverick about multiple reliability issues and early adopters were being left with basically unfixable forks (and matching frames and droppers if they really went full brand) it was too late. Besides, there was almost certainly another fork or new thing to talk about that would get more attention than the workshop fix feature for the fork we hid at the back of the mag.

And that unfortunately is where we still are today. In fact, it’s arguably worse in some cases as the internet creates an even more instant demand for a ride assessment of a new product. And the more elements it adds to the established parts list or performance algorithm, the more unreliable those conclusions inevitably are. The only thing we can do is publish first rides that are informed with as much relevant experience as possible and then wait until we’ve got enough riding into a product to really call it with a full review. Even then it’s still a scary stick your neck out moment when you’re the first to put your full-fat opinions on the line.

So at the end of the day, it’s up to you really. Carry on riding what you know and love or get sucked into the hype and hope of a new standard as soon as it breaks cover and hope you, the manufacturer and the media who called it the ‘best idea ever’ gambled right.

And yes I know that’s far from ideal, but then if there wasn’t an element of risk in your psyche you’d probably be a time triallist and not a mountain biker, and where would the excitement be if there was no progression or promise of ‘even better’ to keep us stoked?

Guy Kesteven has been working on Bike Perfect since its launch in 2019. He started writing and testing for bike mags in 1996. Since then he’s written several million words about several thousand test bikes and a ridiculous amount of riding gear. He’s also penned a handful of bike-related books and he reviews MTBs over on YouTube.

Current rides: Cervelo ZFS-5, Specialized Chisel, custom Nicolai enduro tandem, Landescape/Swallow custom gravel tandem

Height: 180cm

Weight: 69kg