Do electric mountain bikes have gears?

We help you understand why e-bikes have gears, instead of a gearbox

For those riders considering their first e-bike, there can be much confusion about the function of the drivetrain, gears and chain.

It is important to understand that e-bikes are not mopeds. You can’t trigger an e-bike’s battery assistance without pedal input. It doesn’t have a hand throttle, which is important, and it's the reason why e-bikes are allowed into wilderness areas.

E-bikes use conventional drivetrains, with a rear derailleur tensioning the chain and shifting up and down the cassette. If you look at any battery-assisted dual-suspension model from our list of the best e-MTBs, it looks like a standard mountain bike. The only external clues to the e-bike’s battery and motor are thicker downtubes and bottom brackets.

When choosing from the many e-MTB motor options, a lot of e-bike designers prefer the mid-drive motor configuration because it hides the drive unit in your e-bike bottom bracket.

For decades, mountain bikers have been dreaming of replacing the rear derailleur and exposed cassette with a sealed gearbox. Although there are proven gearbox designs used in boutique dual-suspension mountain bikes, produced by the likes Zerode and Nicolai, the traditional derailleur remains very much in use, and the mountain bike gearbox revolution has yet to begin.

- Best budget e-MTBs: great e-mountain bikes that won't break the bank

Two devices, competing for one space

Why aren’t gearboxes more popular and used by e-bikes? The issue that has prevented gearboxes from being broadly adopted by mountain bike designs is amplified in an e-bike: shifting gear under load.

On an analog mountain bike with a gearbox, riders have to momentarily stall their pedal stroke when shifting. This is unlike a normal derailleur drivetrain, which can be shifted under larger pedaling loads, for example, when climbing up technical terrain.

E-bikes produce two or three times' the power of an average mountain biker. This creates a much greater strain on the drivetrain, making it tricky to manage with current mountain bike gearboxes and their limited ability to shift under load.

The sophisticated mechatronic calibration that has become a feature of e-bike engineering could possibly find solutions for shifting under load, but e-bikes have a bigger gearbox problem: space.

Rear-hub motors are the configuration for road and gravel e-bikes, but they are less ideal for dual-suspension mountain bikes. The significant increase of weight around the rear axle undesirably influences suspension kinematics. This would theoreticality make a dual-suspension mountain bike with a rear-hub motor feel odd in tight switchback corners – not to mention drop-offs or jumps.

The mid-drive motor has prevailed as an e-bike design for mountain bikes, because it concentrates the additional electric motor weight where it can be advantageous, instead of detrimental: the bottom bracket.

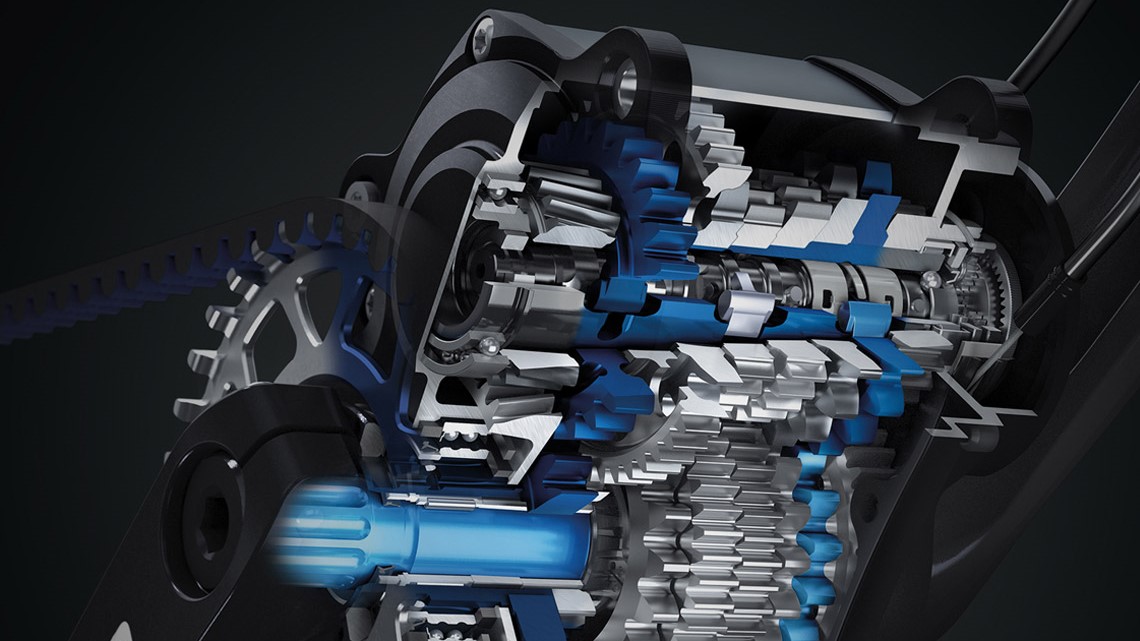

With a pinion gearbox and mid-drive motor competing for the same packaging space on a dual-suspension mountain bike, it’s obvious why you can’t have both.

The Eboxx shows what can be done

Nicolai is an exception in this regard. The German mountain bike frame builder, celebrated for the exceptional neatness of its welds, does produce a range of e-bikes featuring both Bosch mid-drive motors and pinion gearboxes.

On Nicolai's Eboxx bikes, the gearbox and mid-drive motor are mounted next to each other, using a belt drive to transfer power to the rear wheel.

How has Nicolai solved the issue of packing a gearbox and mid-drive motor in the same area? Its long history of being a custom frame brand, with all design and fabrication being done in-house, gives Nicolai the ability to engineer around challenges, instead of having to rely on the resources and willingness of third party contract manufacturers.

It should be noted that Nicolai is a boutique bike brand, producing much fewer bikes per year than most other mountain bike companies. Therefore it can afford the risk of experimentation and more staff hours when producing bikes that are complicated to construct and assembly.

Nicolai's dual-suspension e-bike is also made from aluminum, instead of carbon-fibre, further simplifying the process of creating a construction that will accommodate a gearbox and mid-drive motor around the bottom bracket.

- Best chains for mountain bike, gravel and road

- The best 1x chainrings for mountain bikes: front chainrings for simplified drivetrains

Why fewer gears and chainlines matter

Although you now understand why dual-suspension e-bikes have similar drivetrains to an unassisted mountain bike, there are some differences in core component specification worth noting. With the power available from a mid-drive motor, e-bikes can use fewer gears and run larger chainrings.

The mountain bike drivetrain underwent a 1x evolution over the last decade, thanks to the SRAM XX1 1x11 system, which debuted in 2012. On conventional mountain bikes the default configuration is now a 1x12 drivetrain, but with all that battery power onboard an e-bike, it can do with fewer gears.

You’ll see e-bikes with 1x11 or 1x10 drivetrains. What are the benefits of running fewer gears? Well, this allows the e-bike to operate with a straighter chain line, reducing its wear.

Singlespeed e-bikes are popular with active commuters, but do they work off-road? With only one gear, you’ll draw a lot more battery energy using pedal assistance when climbing, but there are benefits.

A singlespeed e-bike runs the straightest possible chain line, limiting lateral strain and wear. For gravel and adventure bike riding, a singlespeed offers the lowest possible mechanical complexity. You might knock a derailleur out of alignment with a drivetrain e-bike, but on a singlespeed there is no risk of damaging your only gear.

For riders venturing days away from the nearest bike shop or online purchase delivery point, the singlespeed e-bike has terrific durability and the lowest risk of being stranded, due to drivetrain failure.

- Best MTB groupsets: the best mountain bike groupsets tested

- Best mountain bike brakes: Bike Perfect's pick of the best MTB brakes

More than a century of derailleur evolution benefits your e-bike

The fact that your e-bike has a standard mountain bike drivetrain makes it much easier to maintain and repair. You benefit from all the knowledge that mechanics have developed over decades, working on mountain bike drivetrains.

There is also the issue of scale and parts availability, which is leveraged by the enormous legacy mountain bike market. The similarity in drivetrain between normal dual-suspension mountain bikes and their e-bike equivalents means you can easily find parts, without having to worry about weird standards of incompatibility.

E-bike drivetrains might be a bit heavier, with more durable metal used in their cassettes and chains, but those additional grams are easily compensated by the energy in your battery.

The dual-suspension e-bike has simply taken the proven design of derailleur drivetrains, and made them a bit tougher to absorb that extra power output.

Lance Branquinho is a Namibian-born journalist who graduated to mountain biking after injuries curtailed his trail running. He has a weakness for British steel hardtails, especially those which only run a single gear. As well as Bike Perfect, Lance has written for MBR.com, Off-Road.cc and Cycling News.