Early Verdict

The Atherton's downhill bike is already a World Cup winner but with cutting edge manufacturing tech and an ecosystem that will only drive further development, we get the feeling Atherton Bikes are only just getting started.

Why trust BikePerfect

The Athertons are synonymous with not just mountain biking in the UK but across the world. The siblings have proven successful in both downhill mountain biking and freeride on the international stage throughout the years, from Downhill World Championships to events like Red Bull Rampage.

Their influence and input into the sport have transcended competing as well, the family unit has morphed into a wider downhill team, run probably the hardest downhill race on the calendar, built one of the most progressive Bike Parks in the UK, and, last but not least, developed one of the best downhill mountain bikes and enduro bikes around.

The bikes are some of the most unique designs available too. Rather than use alloy or a carbon mold, Atherton Bikes uses carbon tubing which is essentially cut and glued into 3D printed titanium lugs. This method opens up a wealth of possibilities in regards to sizing and geometry, drawing from decades of combined racing experience from Gee, Dan, and Rachel, and is paired with a suspension system designed by the legendary Dave Weagle.

We got the opportunity to take a nosey around Atherton Bikes facility in Wales as well as take Continental Atherton Racing team rider Dom Platt’s old race bike out for a spin on its home turf, Dyfi Bike Park. Keep reading as we take a close look at the Atherton Bikes AM.200 downhill bike to see what makes it so unique.

Design and specifications

The Atherton Bike HQ is a somewhat unassuming building tucked down the back of a small Welsh industrial site with little from the outside that hints at what goes on within. Inside it feels even smaller, with much of the magic happening across just three rooms.

While the construction methods are unique when compared to other carbon downhill bikes on the market which are layered up inside a carbon mold, it isn't new and we have previously seen this design under another name. Robot Bikes initially came to the market with this design but was later absorbed and developed into the Atherton Bikes project. The process itself is relatively simple on paper, lugs are 3D printed from Titanium before being mounted into jigs where everything is glued together, of course, the actual designs and process are far more intricate in practice.

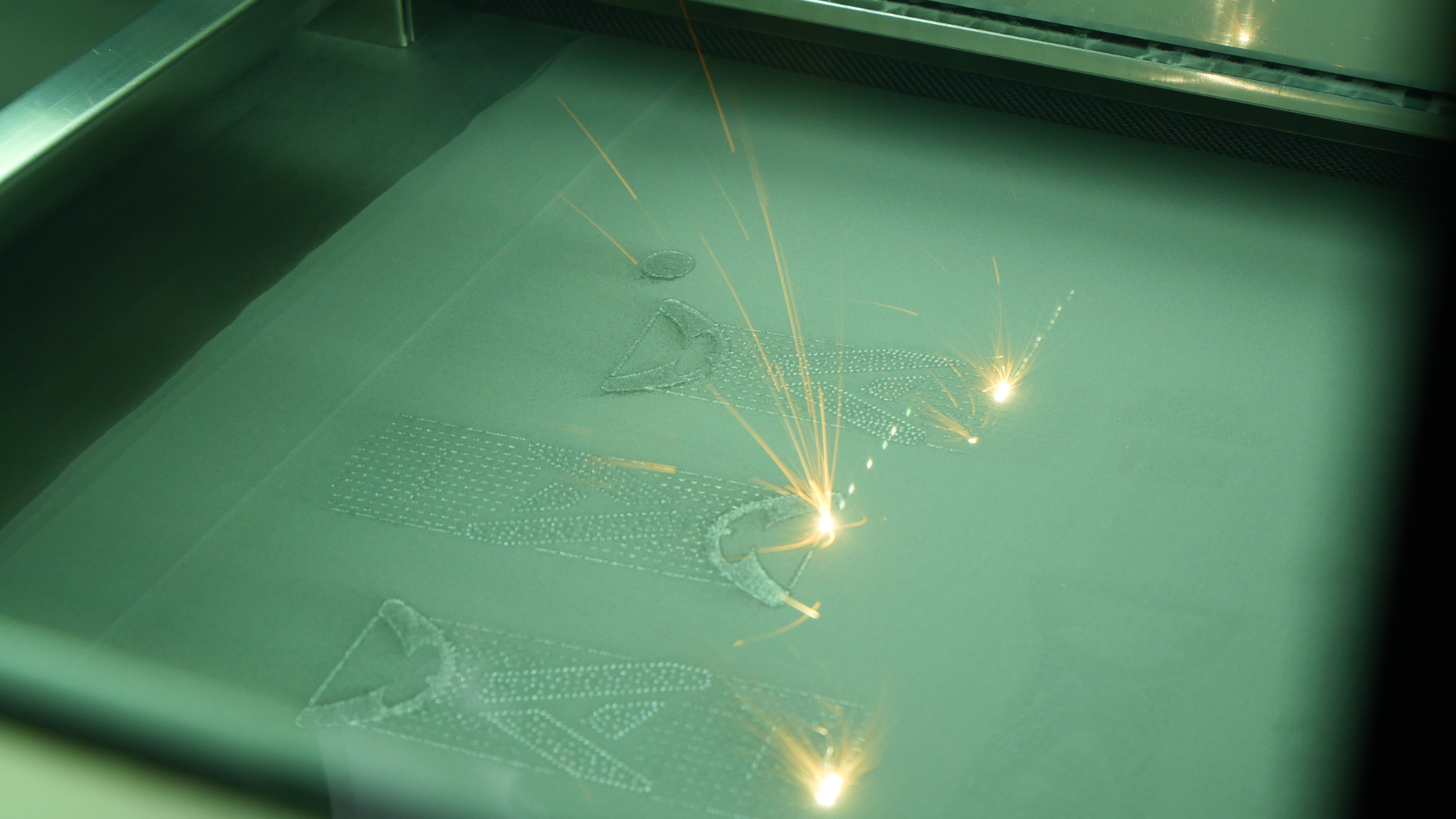

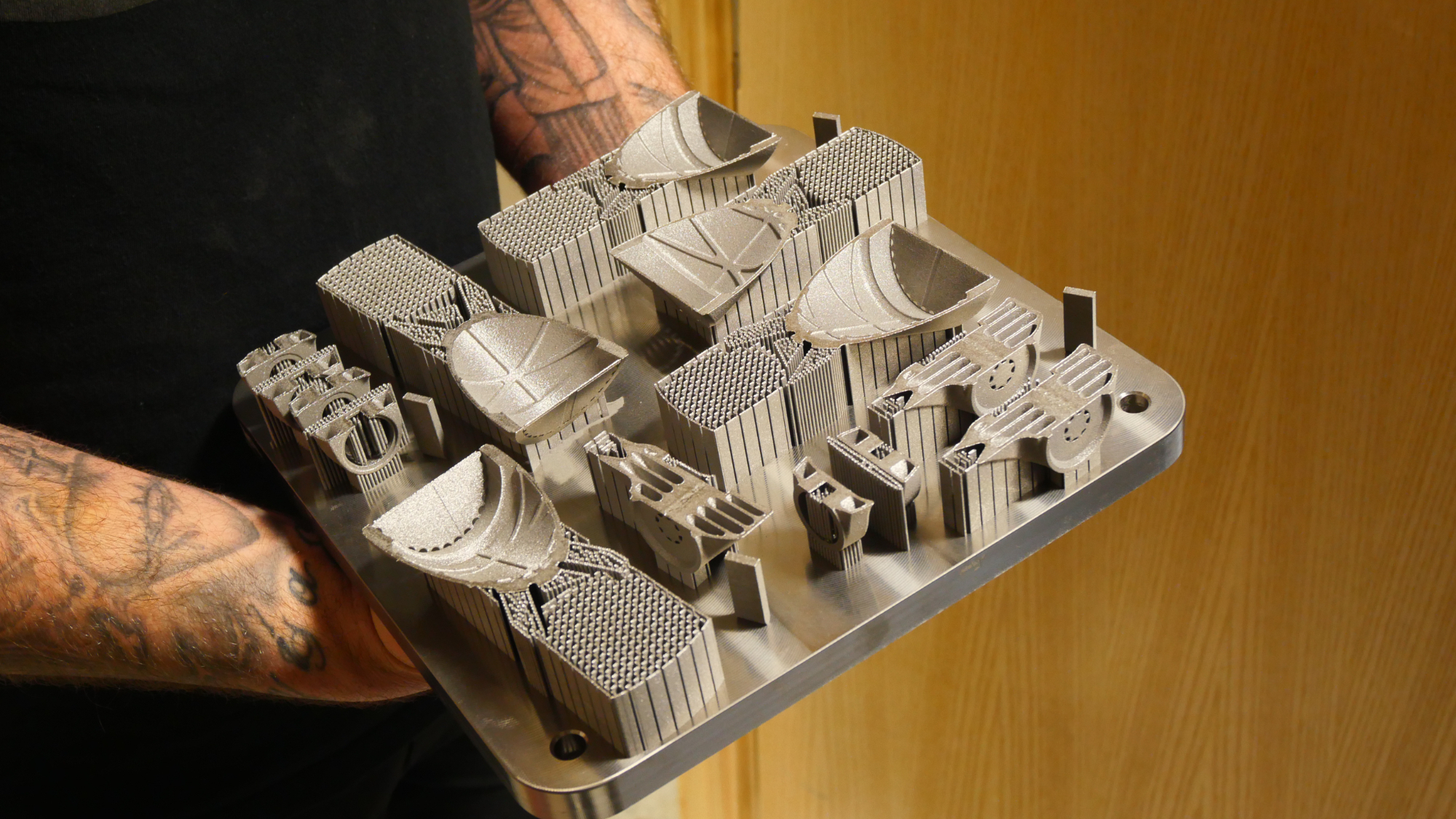

Every Atherton Bike starts its life within the huge Ren AM 500Q 3D printer. Lasers melt the aerospace-grade Ti6Al4V particles together to form fantastically intricate shapes and webbing. A full bike's worth of lugs is produced on a single slab, all of which are tracked and documented for future reference. Once formed, the lugs are heat-treated and bearing races are CNC machined.

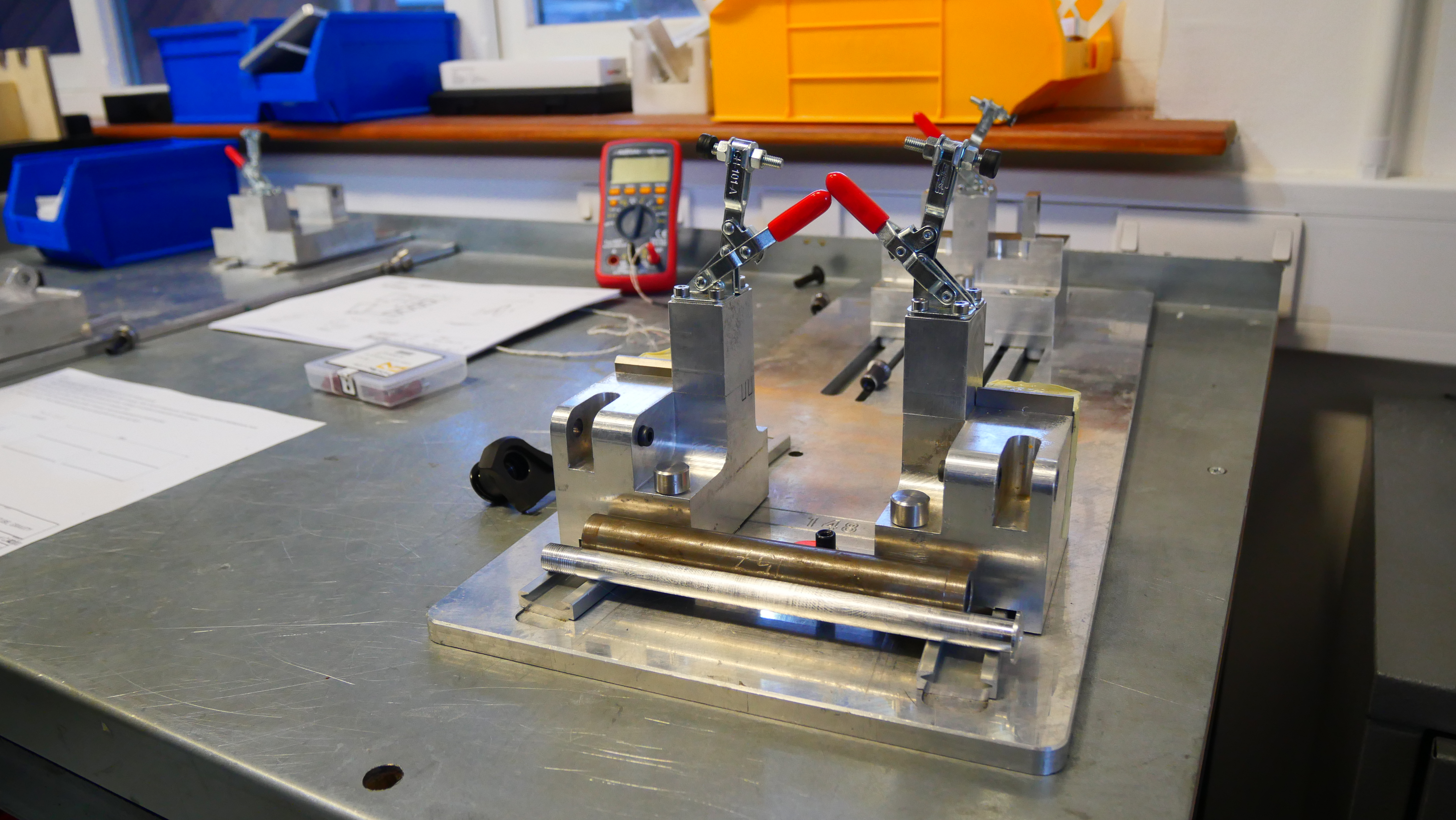

The manufacturing of the lugs doesn't take much more than the press of a button, it's the gluing of lugs to carbon tubes where much of the hands-on work is required. The gluing room is littered with frame jigs that look like surgical torture devices, each holds the lug and corresponding tube perfectly so that they can be slid together in a very satisfying manner. Getting everything glued together takes around half a day which is then followed by the curing process.

The flexibility and efficiency of the lugged design mean that Atherton Bikes are able to offer an unmatched range of sizing on its bikes. The downhill bikes come in 12 different sizes ranging from a reach of 410mm, right up to 520mm. Seat tube lengths are 420mm across all bike sizes so riders have no limitations when it comes to finding the perfect sizing. The 63-degree head angle and 350mm bottom bracket height remain the same across all sizes. When it comes to stack and chainstay length, the sizing is split into three sizes; 627, 636, and 645mm of stack and 445, 450, 455mm for the chainstays.

Sizing options don’t stop there either, because every bike is made-to-order Atherton Bikes can even offer custom sizes – something basically unheard of for consumer downhill bikes. Plumb in your dimensions and the website will pump out what it recommends as your perfect size bike. It does add an additional £650 to the frame price but if you are extremely picky over reach numbers the option is there.

Being able to construct a frame from individual elements has another major benefit. Atherton Bikes are able to easily experiment and prototype with different tubes and geometry without significant outlay. I rode the first version of the AM.200 however there is now a second-generation that uses the seat stays from the Atherton’s enduro bike as it offers a preferred level of stiffness and now has full internal cable routing.

The downhill bike features 200mm of travel which is managed by a DW6 linkage, the same linkage is also used on the enduro bike. Atherton Bikes brought in Dave Weagle who reworked his legendary 4-bar linkage design, adding two more pivots which are said to improve small bump sensitivity and increase traction.

Platt signed to Atherton Racing team last year after making his mark on the UK domestic scene riding for Atherton Academy, winning just about everything he raced including the UK Downhill and Enduro National Champs. Dominic is undoubtedly a young talent who is going to thrive under the mentorship and support of such a team. Platt raced his first World Cup at the 2022 season opener in Lourdes and while a tumble tarnished his race run, he was still pleased to finish 17th on his debut.

His former race bike is, as you would expect from a top-level race bike, kitted out with some serious kit. Fox suspension front and rear, a SRAM XO 7-speed downhill drivetrain, and Stans Flow wheels. Continental, who are now title sponsors of the Atherton race team fitted the bike with its new Kryptol front and rear tire which was recently announced as part of the German tire brand's full new gravity range.

One of the spec highlights was the exceedingly premium and wonderfully executed Trickstuff Maxima brakes. The fully CNC machined levers and calipers are beautifully designed, believe the hype when it comes to performance too as the light lever feel and controllable power is unlike anything I have ever used before.

The bike is finished with an FSA Gradient Carbon handlebar and direct mount stem, ODI grips, a WTB seat, and Crank Brothers Stamp 7 pedals.

In the bike park

I have to admit my experience with downhill bikes is limited. I’ve not ridden a downhill bike in 15 years and haven't even swung my leg over a bike with more than 120mm of travel for a couple of years. Never mind dropping into Dyfi Bike Park where even with my trigger-happy brake fingers I was still railing through berms at 40kph.

It's here that you can truly see how the whole Atherton ecosystem comes together. Dan has free reign to carve what he wants from the dramatic Welsh landscape building technically demanding tracks to replicate those on the World Cup circuit. While I might have stuck to the inclusive Super Swooper, relatively manicured 50 Hits and El Hippo, above the uplift drop-off point you can see the scratchings of track that Gee rode in his incredible ‘The Ridgeline’ video. Not only is Dyfi an excellent playground for riders, but it's also a training facility and a testing ground for the downhill team and Atherton Bike to dial in the riders, bikes, and new products. Allowing riders to push themselves and the products they use.

Despite dropping into the proverbial deep end, it was amazing how comfortable I quickly found myself aboard the bike. The high speeds of Dan Atherton's Dyfi creations leave nowhere to hide, coaxing riders to ride as fast as they dare. The trails frequently pitch into ragged shale chutes where the balanced central positioning on the bike feels like a calm epicenter whilst the chaos goes on around you. It's a great place to be, especially if you are being brave, resisting the braking urges, and pushing your limits.

It didn't take long to become more comfortable and with every run, I felt as if I was able to ride harder to get a better feel for the bike. Steering felt calm and controlled whether diving into tight berms or railing high-speed trail sections and as I began hitting features harder I could feel the suspension coming more into its own. While we dialed in what suspension settings we could I think there was plenty more fiddling possible and eke out more performance for my riding. Namely, the coil shock as I think I would have been better served with a lighter spring. Dom is roughly around the same weight as me but I suspect the junior World Cup racer is also hitting everything a lot faster. That said there were plenty of fast sections where I could feel, or rather not feel, the suspension working and the whole bike would feel increasingly settled and controlled.

The Athertons seem to have the perfect setup, a small section of Wales dialed to the development of some of the best riders and bikes. Each element of the system feeding the others in a constant process of progression. It's a safe bet that we are still to see some big things from the Athertons.

Tech Specs: Atherton Bikes AM.200 downhill bike

- Price: Prices start at £4,100 frame only, builds retail for £6,800.00 - £8,400.00

- Model: Atherton Bikes AM.200

- Discipline: Downhill

- Head angle: 63-degrees

- Frame material: Titanium lugs with carbon tubing

- Wheel size: 29 x 2.4in

- Suspension: Fox 40 Factory / Fox DHX2 Factory

- Drivetrain: SRAM XO, 7-speed

- Cranks: FSA Gradient

- Brakes: Trickstuff Maxima

- Cockpit: Giant Contact SLR XC Flat (760mm) handlebar and Giant Contact SL XC (70mm) stem

- Wheelset: Stans No Tubes Flow

- Tires: Continental Kryptotal 29x2.4 tires

- Seatpost: FSA

- Saddle: WTB

Graham Cottingham joined the BikePerfect team as our senior tech writer in 2020. With over 20 years of riding experience, he has dabbled in downhill, enduro, and gravel racing. Not afraid of a challenge, Graham has embraced bikepacking over the last few years and likes nothing more than strapping some bags to his bike and covering big miles to explore Scotland's wildernesses. When he isn’t shredding the gnar in the Tweed Valley, sleeping in bushes, or tinkering with bikes, he is writing tech reviews for BikePerfect.

Rides: Cotic SolarisMax, Stooge MK4, 24 Bicycles Le Toy 3, Surly Steamroller

Height: 177cm

Weight: 71kg

What is a hands on review?

'Hands on reviews' are a journalist's first impressions of a piece of kit based on spending some time with it. It may be just a few moments, or a few hours. The important thing is we have been able to play with it ourselves and can give you some sense of what it's like to use, even if it's only an embryonic view.